Why aren’t my barcodes scanning?

Barcodes are used for important tasks around the world, for example EAN 13 for identifying and tracking retail products. 2D barcodes such as Data Matrix and QR codes are also widely used for part labelling. Today we dive into why your barcodes might not be scanning.

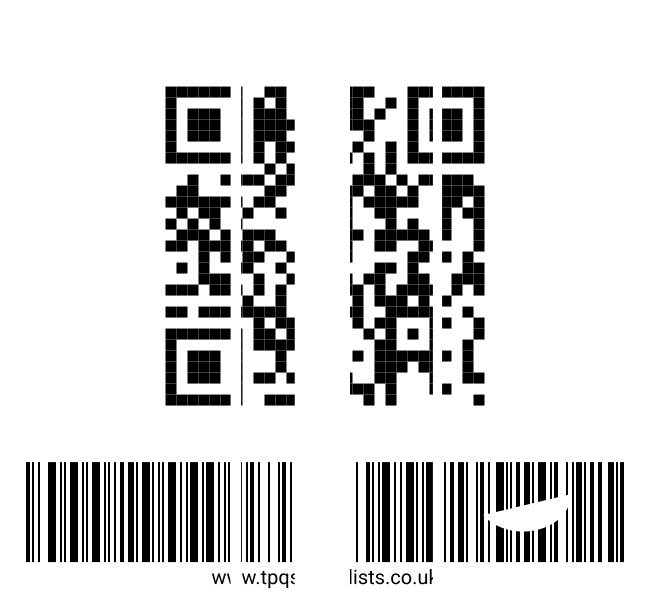

The quiet zone is too small

Most barcodes are surrounded by something called a quiet zone. The quiet zone is just the empty space around the barcode and is called the quiet zone because it doesn’t contain any data. A decoding device such as a mobile computer or barcode scanner uses the quiet zone to identify the start and end of a barcode. Things like poor label design, incorrect printer settings, improper media loading or even issues with the label printer drive system usually lead to problematic quiet zones.

The barcode is blurry

Blurry barcodes won’t scan, the width of the lines and squares in the case of 2D barcodes is used to tell the decoding device what character it represents. If these lines aren’t crisp the decoding device will struggle to interpret the data. This blurriness on thermal printers is often caused by the print head temperature being set too high, a mismatch between the ribbon and labels or using a ribbon with direct thermal labels.

The barcode is faded

When a barcode is faded it will cause problems for the decoding device. 1D barcodes have a start and end sequence which tells the decoder which side is the start and end of the barcode. Fading on one side may effect the decoders ability to recognise the start or end sequence, if both are not present it will not be recognised as a barcode. You need the printed barcode to stand out from the background as much as possible for it to scan. Common causes of this fading are incorrect pressure settings, worn platen rollers, a dirty print head, the print head temperature being set too low and even expired direct thermal or thermal transfer labels.

Print quality voids

Voids in the barcodes print quality such as a print head element failure. Which can be as small as the width of a strand of hair can stop a barcode from scanning. Other print quality voids such as ribbon wrinkle or missing chunks due to a damaged platen roller can also do the same. These missing parts could render the barcode out of spec and undetectable by decoding devices.

Faulty decoding device

Mobile computers and barcode scanners can also develop faults that will stop good barcodes from being decoded. They are complex devices that need to be setup correctly to decode the correct symbology’s. A dirty, scratched or damaged lens covering the decoder is a common culprit. The scan engine or triggers can also develop faults stopping operators from decoding efficiently or sometimes completely.

Conclusion

In order for a barcode to be decoded effectively and consistently:

The label design has to be completed professionally taking any quiet zones or symbology specifications into account.

The thermal printer has be properly setup and maintained to produce a good quality print.

The labels being used for printing have to be in date, the best way to do this is using stock rotation.

The decoding device needs to be in good working order.

If you are encountering any barcode related issues due to any of the factors mentioned above, please contact us for a professional diagnosis or repair of thermal label printers, mobile computers or barcode scanners.

Thank you for reading, I hope you learned something.