Direct Thermal vs Thermal Transfer printing!

Direct thermal and thermal transfer are two different ways of producing an image onto a label using a thermal printer. In this article we are going to explain how they work, discuss what the key differences are, the advantages/disadvantages of both technologies and the questions you should be asking when deciding which technology is best for your application.

WHAT IS DIRECT THERMAL AND THERMAL TRANSFER PRINTING?

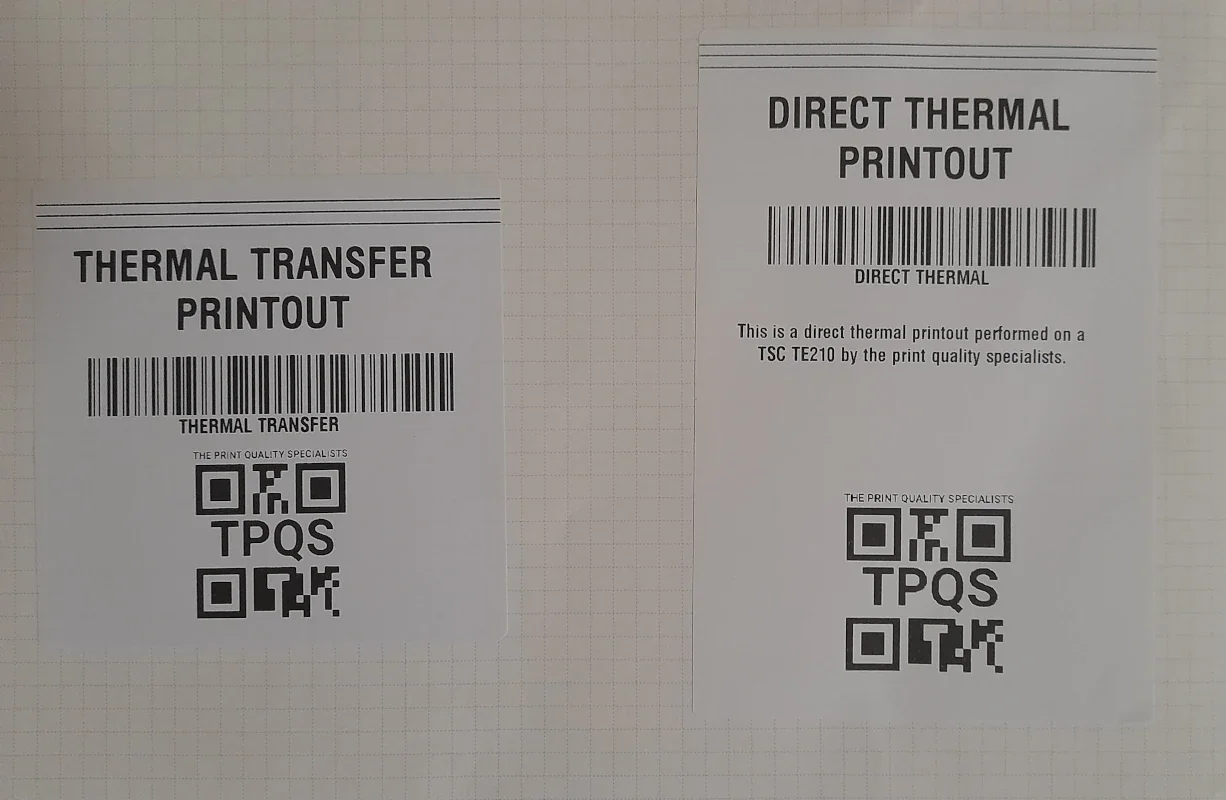

Let’s start with direct thermal, the easiest way to think of direct thermal printing is to imagine the ink is in the labels. When heat and pressure is applied to a label with a special coating, the coating reacts to that heat and pressure by going dark. The high sensitivity to pressure, heat and light is a major limiting factor making it unsuitable for long term applications. Thermal transfer on the other other hand requires a ribbon and labels to produce an image, when heat is applied to the ribbon the ink from the ribbon is transferred to the label hence the name thermal transfer! You can get a variety of different ribbon and label types that when combined together correctly give the image special properties such as scratch and chemical resistance.

KEY DIFFERENCES

The key differences between the two printing technologies are as follows:

DIRECT THERMAL PRINTING REQUIRES ONLY A SPECIAL LABEL WHEREAS THERMAL TRANSFER PRINTING REQUIRES LABELS AND RIBBONS

THERMAL TRANSFER PRINTING IS SUITABLE FOR A WIDER RANGE OF APPLICATIONS

DIRECT THERMAL LABELS WILL FADE OVER TIME WHEN EXPOSED TO LIGHT AND HEAT WHEREAS THERMAL TRANSFER LABELS WON’T

DIRECT THERMAL APPLICATIONS HAVE LOWER CONSUMABLE COSTS

DIRECT THERMAL ONLY PRINTERS ARE USUALLY MORE COMPACT THAN THERMAL TRANSFER PRINTERS

DIRECT THERMAL PRINTING ADVANTAGES & DISADVANTAGES

A big advantage of direct thermal printing is cost, you only have to purchase labels instead of labels and ribbon saving you money on consumables. Another advantage is it’s easier to implement, you only have to train operators on loading the label rolls into the printers and not faffing around trying to load the ribbon as well. This makes it quicker to change the consumables and less training is required, so it’s very desirable for fast paced environments where staff turnover might be higher. A major disadvantage is the sensitivity to light, heat and pressure limiting them to short term indoor applications as you can’t guarantee the label won’t begin to fade. This can take up to 6 months but heavily depends on the environment of the label and quality of the label. A final disadvantage is direct thermal printers often live a hard life with labels dragging all the dust, dirt and debris from their environment through it. This means maintenance such as printhead and platen roller replacements are required more often.

THERMAL TRANSFER PRINTING ADVANTAGES & DISADVANTAGES

Not having to worry about your printed image performing a houdini style disappearing act is a major advantage for thermal transfer printing. It’s no where near as sensitive to heat and light. You can also get many different combinations of ribbon and labels that offer special properties such as scratch and chemical resistance, making them suitable for a wide range of indoor and outdoor applications with the right stock! It’s not all black and white rainbows though, the addition of a ribbon makes loading the printer more complicated, so it will require more training and take longer. The ribbon also unlocks the potential to cause a barrage of further printer issues as now you have a ribbon sensor, the consumables must match to get an adequate transfer, more print quality faults from improper maintenance such as ribbon wrinkle. A final advantage is that a ribbon acts as a shield for the printhead, often leads to longer printhead life and as a result less overall printer maintenance.

WHICH SHOULD YOU CHOOSE FOR YOUR APPLICATION?

After I’ve babbled on a lot and probably repeated myself a few times, you should have a better understanding about direct thermal and thermal transfer printing. When picking a thermal printing technology for an application you must answer these important questions.

What environmental conditions and elements is the label going to be subject too? such as what heat, light and chemicals throughout it’s life.

What are you applying the label too? A cardboard box has different requirements from a chemical drum believe it or not.

How long the label needs to last? Be it 1 day or 1 year.

How many rolls of labels do you expect to consume over a year? So you can weigh up the consumable cost implications.

Answering these questions using the information provided above should tell you whether direct thermal or thermal transfer fits your application best. Thank you for reading, I hope you found it useful and if you are looking to purchase a thermal printer in the UK please get in touch we’d love to help you discover the perfect fit for your application.